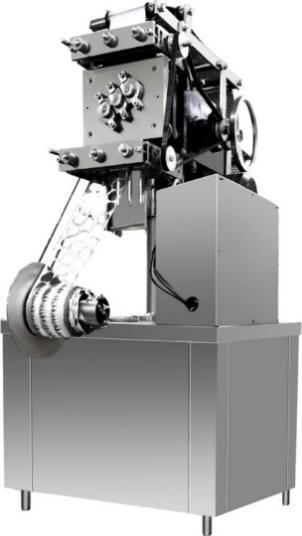

Rinser Filler Foil seal Electric heating sealing system

Rinser Filler Foil seal Electric heating sealing systemAluminum foil sealing systemThis machine is based on the introduction of imported filling technology, combined with the company's many years of production experience after the development of new products. Set automatic bottle feeding, bottle washing, filling, capping, capping, sealing as one of the multi-functional combined unit, scientific and reasonable design, beautiful shape, easy operation and maintenance, high degree of automation. The filling is connected to the power supply, and the production conditions are met in each part (whether the liquid level in the cylinder reaches the set value, whether there is an aluminum cap on the guide rail of the punching cap machine, whether the compressed air reaches the set pressure, and the treated material meets the process requirements, the empty bottle is sent to the turntable of the bottle sorting machine by the elevator, and the empty bottle is transferred to the bottle parting screw of the filling machine by the conveyor belt after the bottle is managed. At the same time, the star wheel is inserted into the bottle punching machine. The rotary plate of the bottle punching machine is equipped with a stainless steel bottle clamp, and the bottle clamp is turned 180° along a guide rail to make the bottle mouth downward. In a certain area of the bottle punching machine, a special nozzle sprays bottle flushing water to wash the inner wall of the bottle. After the bottle is rinsed and drained, it is then turned 180° along the guide rail under the bottle clamp to make the bottle mouth upward. The washed bottle is exported from the punching machine and transferred to the filling machine through the transition wheel. The empty bottle is sent to the corresponding filling valve center of the filling machine through the flushing wheel. At the same time, the bottle holder lifts the empty bottle under the action of the guide rail, extends into the filling valve, and opens the filling valve. At this time, the logistics fan into the bottle along the filling valve core, and the air in the bottle returns to the cylinder through the center of the vent tube. When the bottle goes to a certain position, the bottle drops, the filling valve is closed, and then the bottle holder is lowered, and the bottle is pulled out of the filling station by the lower cover star wheel. After the filling is finished, the bottle cap is directly turned on the star wheel of the lower cap to the mouth of the bottle. There is a detection device on the star wheel of the lower cap to detect whether there is no cap of the bottle. If there are more than three empty and no cap, the machine will automatically alarm and stop. |

|

|