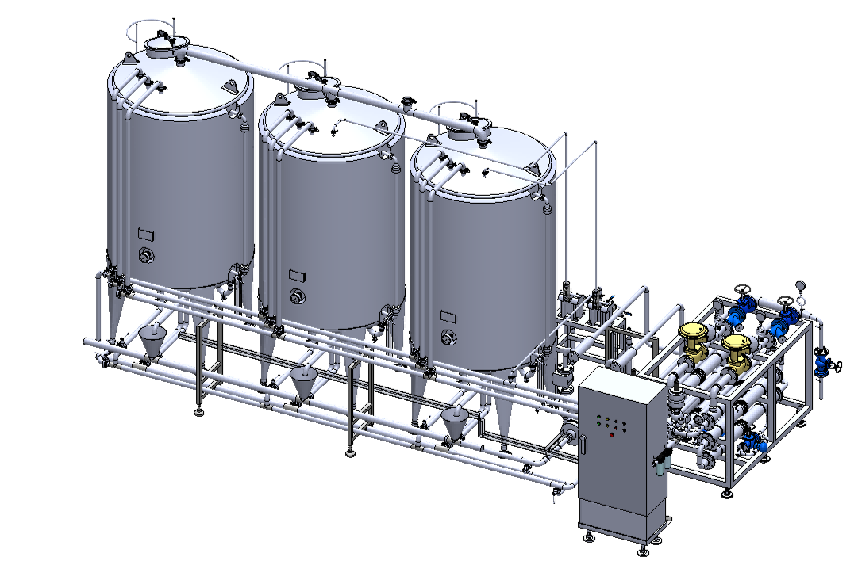

Automatic CIP System

Automatic CIP System1. Equipment overviewCIP cleaning is CLEAN IN PLACE. The system is single loop. The cleaning station is a compact modular cleaning system used in the cleaning cycle of beverage production line, which can carry out hot and cold cleaning cycles. The CIP cleaning station is automatically controlled. During cleaning, the system can realize the automatic adjustment of cleaning temperature and cleaning liquid concentration according to the setting. In the CIP process, according to the reflux cleaning liquid concentration, pressure and other parameters, the cleaning liquid can be automatically recovered according to acid, alkali and hot water. 2. Equipment characteristics1) Temperature automatic control, through the outlet temperature probe to control the opening of the steam flow regulating valve size, to ensure that the cleaning temperature within the allowed range (control accuracy ±2℃); 2) Cleaning fluid supply and self-circulation switch automatic control, through the cleaning fluid outlet valve switch; 3) Equipped with online conductivity meter, can intuitively monitor cleaning and reflux concentration and control the selection of recovery and discharge; 4) Automatically add chemicals with pneumatic diaphragm pump; 5) Tank sampling valves and manual valves that need to be operated frequently are installed on the operating surface for easy operation by operators; 6) The backflow line is equipped with a sampling valve, which is convenient for manual detection of cleaning liquid concentration. |

|

|