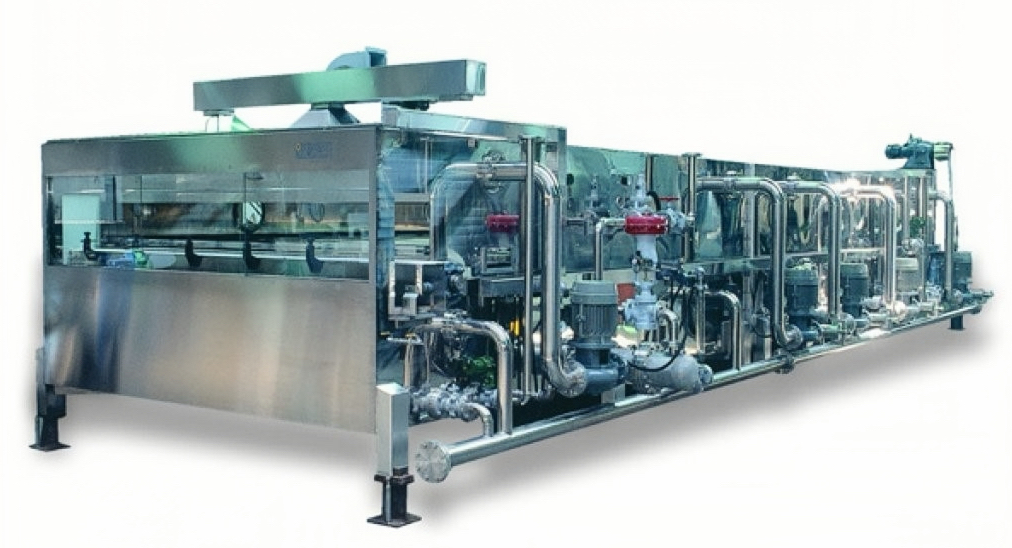

Auto Pasteurization Tunnel

Auto Pasteurization TunnelPLSJ3815 spray machine is a new design of digestion and absorption of similar equipment technology at home and abroad, using hot water heating 1, hot water sterilization 2, warm water cooling 3, tower water cooling 4 and pure water spraying five stages of treatment, cooling time according to user requirements of frequency conversion speed regulation. Two sets of plate heat exchangers are used for hot water heating 1 and hot water sterilization 2, respectively, to ensure the thermal sterilization (pasteurization) of the tank and the materials in the tank; Lukewarm water cooling three, tower water cooling four to the tank material step by step cooling, to meet the needs of production equipment and technology; The final spray of purified water is intended to make the cooled Steel Can (tank) dry without water marks. The equipment is equipped with automatic metering pump, which can adjust the dosage according to the technical requirements or the supplementary water. Hot water is generated by the heat exchanger and flows into the sink after use for recycling. If the temperature of the spray water does not reach the set temperature, the heat exchanger will be properly heated by the actuator. The warm water in the water tank of the spray machine is cooled by the heat exchanger and the cooling tower outside the workshop after being recycled. |

|

|