Aluminum Bottle Washing Filling ROPP Capper

Aluminum Bottle Washing Filling ROPP Capper

Aluminum Bottle Washing Filling ROPP Capper

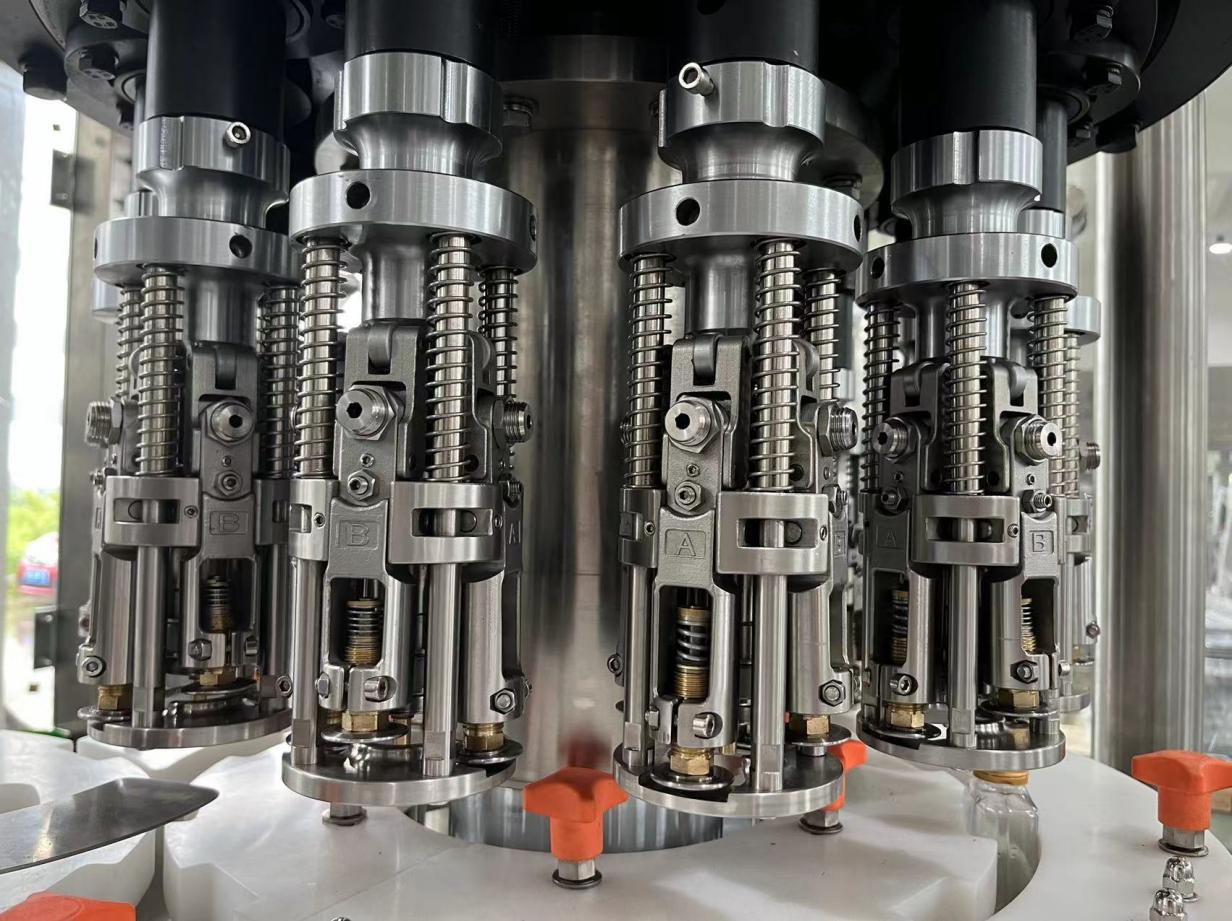

Aluminum Bottle Washing Filling ROPP CapperSummaryThe bottle is transferred to the three-in-one bottle punching machine by the bottle feeding screw + bottle splitting wheel assembly through the empty bottle conveying. The rotary plate of the bottle punching machine is equipped with a flipping bottle clip, which holds the bottle mouth and turns it 180°along the guide rail to make the bottle mouth downward. In the specific area of the bottle punching machine, a special nozzle sprays bottle punching water to wash the inner wall of the bottle, while washing the outer wall of the bottle. After the bottle is rinsed and drained, it is then turned 180° along the guide rail under the bottle clamp, so that the bottle mouth is upward. Through the transition wheel and the corresponding guide retainer, the washed bottle is taken out of the punching machine and sent to the filling machine. The bottle entering the filling machine is kept by the bottle plate on the bottle lifting mechanism, and the bottle rises and falls under the action of the bottle lifting mechanism and the CAM. The bottle lifting mechanism rises to make the bottle mouth contact and open the filling valve to complete the filling process. After the filling is finished, the bottle lifting mechanism is lowered under the action of the CAM, and after falling to the lowest point, the transition wheel and the corresponding guide retainer take the filled bottle out of the filling machine and send it to the capping machine. The double wheel and guide on the capping machine protect the bottle body and keep the bottle upright. The capping head keeps revolution and rotation on the capping machine, and realizes the actions of one capping, opening, two capping and removing under the action of the CAM to complete the whole capping process. The finished bottle is transferred from the capping machine to the bottle conveyor chain through the bottle pulling wheel, and the three-in-one machine is transmitted through the conveyor chain. RinserAll punching clips are produced in strict accordance with the company's requirements and accuracy, to ensure that each part in each bottle clip can achieve interchangeability, effectively reducing the customer's after-sales maintenance and the company's inventory costs and expenses. FillingFilling temperature 88 ℃ Filling valve structure design is reasonable, fast flow rate, high precision. All parts are processed by CNC and machining center equipment. Improve the machining accuracy and ensure the good interchangeability of parts. All filling valve seals are ozone - and corrosion-resistant. All parts in contact with logistics should be made of sanitary materials. Valve and filling bottle hoist sliding sleeve adopts Germany igus corrosion resistant bearing without maintenance. Through the whole lifting device of the filling machine, the liquid level height can be limited and adjustable. The working process of the Valve is as follows: In the rising process of the bottle, the bottle mouth contacts the sealing gasket of the filling valve, continues to rise to open the filling valve, and starts filling. When the liquid level reaches the height of the return pipe, the filling will automatically stop. At the end of filling the bottle lifting mechanism is lowered under the action of pulling down the CAM to make the filled bottle leave the filling valve. Filling Valve features 1.The filling method is gravity filling 2. high-speed, high-precision liquid level, flow rate up to 120ml/s, liquid level accuracy ≤±2mm 3. the filling valve is equipped with a cleaning cup, which can thoroughly clean the filling valve CIP cycle CappingThe capping machine adopts the latest technology from Italy AROL, and the capping CAM trajectory design is calculated and designed separately according to different customers and different bottle mouths. The capping head adopts magnetic constant torque capping head, capping effect is stable and reliable, capping defective rate is less than 0.2%. The falling cover guide rail is provided with a mechanism to prevent the back cover from passing through and the back cover from taking out. At the same time, a set of photoelectric switches are provided. When there is no cover on the falling cover guide rail, the machine will automatically stop running, which can effectively avoid the appearance of the bottle without cap. 1.The screw cap CAM is forged from 45# high quality carbon steel and cut by machining center. In order to improve the strength of the CAM guide rail, the surface is blackened after the corresponding heat treatment. 2.The screw cap adopts a four-spring special ROPP cover screw cap, each set of screw cap to ensure the interchangeability of parts at the same time, in order to facilitate customers in the maintenance process to adjust different torsion, each screw cap is marked with a torque scale. Wheel assemblyThe wheel assembly is made of high-quality stainless steel material and matched with high-quality oil nylon retainer to ensure the smooth operation of the bottle during the handover process. For different bottle sizes, under the premise of unchanged bottle mouth size, it is possible to quickly change different bottle shapes by replacing nylon parts. Bottle pulling wheel adopts special stainless steel 304 material overall protection sheet to avoid bottle scratch and bottle stability. |

|

|